Thermoelectric cooling is a refrigeration technology that doesn’t rely on Vapor-compression refrigeration. Vapor-compression refrigeration is used widely on almost all air-conditioning devices and fridges. This refrigeration systems use high pressure air compressors to cool, they are complex systems and very hard to miniaturize. Thermoelectric cooling is less efficient than the traditional cooling systems but they offer huge advantages: a long life service without any maintenance and flexible shape that is easy to miniaturize and cheap to produce.

Why they are not so popular? Well, they are becoming more and more popular in many fields where intensive and local refrigeration is needed. From CPU cooling to several specialized industrial and lab instrumentation on where refrigeration of sensors, lasers or any little devices is needed to improve its performance and reliability.

What is the thermoelectric effect?

A thermoelectric effect is when a material outputs differences of voltage depending on the temperature, this is a very simple effect that exist on all materials, but it works specially well on metals, as they have a lot of electrical conductivity. Thermoelectric effect was discovered early in the XIV century: by connecting two different metals and setting an electric current to flow thru them it is possible to create a temperature difference between each metal, one will get hot as hell, the other very cold. This is also known as the Seebeck effect.

Thermoelectric effect can be used in two ways: to detect temperature by measuring voltage differences between two metals, this is how thermocouples and many temperature sensors work. Or the other way around, to create temperature variations between two metals by applying current in between them, which is basically a peltier cell or a peltier cooler.

What is a peltier cell?

Peltier cells or thermoelectric cooling devices are able to generate huge temperature differences between the two sides of the peltier cooler when electric current is applied. This devices have a junction of metals inside, and two sides, isolated with a ceramic material.

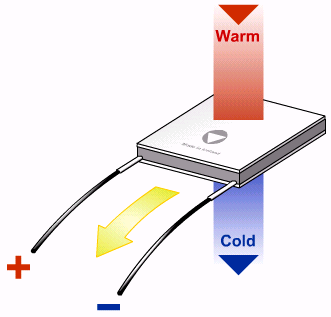

The two sides of a peltier cell: cold and hot side

Representation of the two sides of a peltier cooler

Peltier cells work with direct current, they can draw a lot of current intensity and reliable power sources need to be used. By itself, they do not generate any noise, but forced convection with fans are needed to dissipate the heat generated on the hot side, if not, they won’t last long, and they won’t be efficient.

The colder you keep the hot side, the colder the cold side will get. If the hot side gets too hot it will draw a lot of current, the inner resistance will increase and it will end up burning out. Do not plug peltier cellls directly without any proper heat dissipation, they can be very durable, and quite efficient, but only if there is heat dissipation on the hot side.

For this reason, peltier modules have always attached a dissipation and a fan its hot side.

A peltier cooler – Price around 2$

A peltier with heat dissipation: a fan and aluminum dissipation

A peltier sandwich: dissipation on both sides

What are the use cases for peltier modules?

Air or water refrigeration

What are the peltier use cases for smart gardening projects? This devices are easy to control and set-up, with a relay and temperature sensors controlled by an arduino board they are very useful for many purposes, from temperature control of air or water to air dehumidification and atmospheric water generation.

Peltier modules are extremely useful for making cheap air refrigeration or water refrigeration, specially at low scale on where a standard refrigeration set-up made of air compressors it’s not possible, because they are big and expensive. Very cheap air or water temperature control systems can be build with peltier modules. Water refrigeration is possible and cheap because peltiers are used for CPU refrigeration, so spare parts to build a water refrigeration system are available for a couple of bucks.

Water generation from atmospheric air:

It is possible to use peltier modules to create a water extractor from atmospheric air. Basically, when you refrigerate a humid air condensation will occur, so you can use peltiers modules to generate water from atmosphere.

Air dehumidification:

For the same principle if we can extract water from air by condensation due to the air refrigeration, we could heat again this air and it will be less humid than it was at the beginning of the process. First we refrigerate air, water condensation happens as a consequence of refrigeration. Now we have a colder air and a dryer air, if we heat up again this air at the initial temperature, we’ll have an air dehumidifier build on a peltier. The hot side of the peltier can be used to build this dehumidification system: you only need a peltier and some fans to force convection.

Heating purposes:

The hot side of the peltier can obviously be used for heating purposes, it is not very common because if you do not need the cold side of the peltier, you’ll probably be better using a heating resistance, they are far more efficient for heating. But, of course, peltier can be used for heating purposes.

Guide to buy a peltier cooling system

What has to be taken into account when setting up a peltier cooling system is the voltage and current needs to power the peltier module. So, different power source will have to be used according to its specifications. Often on retail Chinese shops like aliexpress you’ll find them sold as a kit, with dissipation and fans included, but without power source.

What power source do peltiers need?

Most common peltier modules use 12VDC, which is a standard direct current voltage, it’s used in domestic computers. All Peltier modules need very high intensity current sources, the datasheet specification will give you the information about the maximum intensity any peltier module can need.

Micro and mini peltiers use lower voltages, but as they are very current intensity demanding again you’ll have to find a power source that can stand its high current intensity needs, a power source able to give a lot of amperes. This will be easier and cheaper to find for 12VDC, but for lower voltage it’s not so standard.

The higher the voltage on where it’s set to work, the less amperes will be needed to source, so, trying to keep amperage low is a good practice for any electric setup. Unless you have a good reason for not use it, I would stick to standard 12V peltier modules, it will be easier to find a reliable and cheap power source to power them.

Type of peltier modules

All peltier modules use the same principle and have similar design, obtaining the datasheet will let you know how to power them correctly. There are basically 3 series:

- TES1 series: Micro peltier modules that work with low voltages

- TEC1 series: Standard peltier modules from 10x10mm to 80x80mm

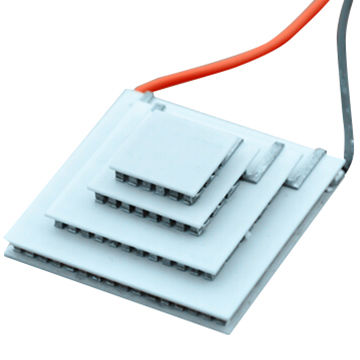

- TEC2 series: Multi-stage peltier modules, basically, is two or more peltier making a pile or a peltier sandwich.

Micro and mini peltier modules: TES1 series datasheet

Datasheet of TES1 micro and mini peltier series.

Standard peltier modules: TEC1 series datasheet

These are the standard size Peltier Thermoelectric modules, ranging from size of 10x10mm to 80x80mm, and

Multi-stage peltier modules: TEC2 series datasheet

Multi-stage peltier modules are designed to provide higher temperature differentials between the hot and cold side than with the standard single modules. The cold side is the little one, the hot side is the wider one. On this setup peltier modules are stacked in a way that the hot side of the last peltier module ( the little one that produce the cold surface ) is kept very cold, so this little peltier will be able to produce a very low temperature, because its hot side is kept cold.

Remember that the colder the hot side stays, the colder will get the cold side.